-

Phone

86-519-88297556

-

Address

No. 21 Taihu Road, Changzhou, Jiangsu, China

-

E-mail

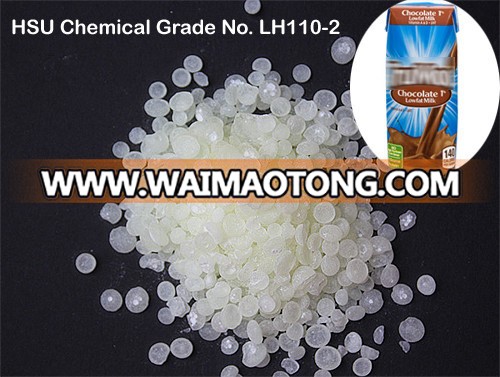

C5/C9 Hydrocarbon Resin for Tape and Label Adhesive

China C5/C9 Hydrocarbon Resin for Tape and Label Adhesive, Find details about China C9 Hydrocarbon Resin, Petroleum Resin from C5/C9 Hydrocarbon Resin for Tape and Label Adhesive - HSU (Jiangsu) Chemical Technology Co., Ltd.

Description

- Model NO.: HS140-5

- Morphology: Solid-State

- Material: Odorless Hydrocarbon Resin

- Main Agent Composition: Thermoplastic Resin

- Promoter Composition: Odorless Hydrocarbon Resin

- Color: Yellow

- Softening Point(°c: 140±5

- Acid Value(Mg KOH/G): Max. 0.1

- Trademark: HSU

- Specification: HS140-5

- HS Code: 3911100000

- Bonding Function: High Temperature Resistant Adhesive

- Application: Automobile, Construction, Woodworking, Footwear & Leather, Fiber & Garment, Packing

- Classification: Hot Melt

- Characteristic: Waterproof

- Composition: Odorless Hydrocarbon Resin

- Grade No.: Hsu™ HS140-5

- Color G#: 5# Max

- Applications: Hot Melt Adhesives, Press Sensitive Adhesives, Ink

- Transport Package: 25kg Per Bag

- Origin: China

C9 Hydrocarbon Resin(cold poly)

TYPE: HS140-5

Item No.HS140-5 is a light yellow granular solid thermoplastic resin, it is produced by ethylene C9 fractions as raw materials in the catalyst, in the normal temperature and normal pressure condition , Generated by the polymerization and the molecular weight range 300-3000 low molecular weight polymer. It has a low acid value, good miscibility, water resistance, resistance to chemicals, ethanol and other characteristics of the acid with a chemically stable, and adjust the viscosity and thermal stability characteristics. C9 petroleum resin is generally not used alone, but as promoters, adjusting agents, modifiers and other resins used together.

Applications:

A, Paint: petroleum resin can increase the added paint gloss paint, paint film adhesion, hardness, acid and alkali resistance.

B, Tires and rubber: tires and rubber is mainly the use of low softening point of C9 petroleum resin. Such resins and natural rubber particles have a good miscibility of the rubber vulcanization process is not a big impact, add oil and rubber tires can play a tackifying resin, reinforcement, softening effect.

C, The adhesives industry: C9 petroleum resin has good adhesion, the adhesive and pressure-sensitive adhesive resin with added oil can improve the adhesive bond strength, acid resistance, alkali resistance and water resistance, and can effectively reduce production costs.

D, The ink industry: petroleum resin, ink, mainly high softening point petroleum resin. Add oil and resin ink color development can play, quick-drying and brightening effects and improve printing performance and so on.

E, Asphalt modifier: asphalt modifier, mainly with high softening point of C9 petroleum resin, increase the viscosity of bitumen to improve asphalt performance, the production of colored surface area; went to the stadium and other sports venues indispensable modified asphalt agent.

F, Other: resin has certain unsaturation, can be used to glue on paper.

Specifications:

Grade No. |

Softening Point(°C) |

Color G# |

Acid Value(mg KOH/g) |

HS140-5 |

140±5 |

5# Max |

0.1-0.5 |

Competitive Advantage:

• Good compatibility with White spirit

• Good chemical stability

• High heat resistance and water resistance

• Giving gloss and short drying time

![[Free Voc] C9 Hydrogenated Hydrocarbon Resin for Adhesive of Auto Car Air Filter](/file/upload/new/201711/07/2012491510056804.24195a01a3643b1160.021444960.jpg)