-

Phone

86-519-88297556

-

Address

No. 21 Taihu Road, Changzhou, Jiangsu, China

-

E-mail

Industrial C5 / C9 Hydrocarbon Resin Pressure Sensitive Adhesives Hg100-5

China Industrial C5 / C9 Hydrocarbon Resin Pressure Sensitive Adhesives Hg100-5, Find details about China Copolymer Resin, C5 C9 Copolymer Resin from Industrial C5 / C9 Hydrocarbon Resin Pressure Sensitive Adhesives Hg100-5 - HSU (Jiangsu) Chemical Technology Co., Ltd.

Description

- Model NO.: HG100-5

- Natural Resin: Copolymer Resin

- Molecular Principal Chain: Copolymer Resin

- Grade No.: Hg100-5

- Color G#: 5# Max

- Trademark: HSU

- Specification: Color G# 5# Max

- HS Code: 3911100000

- Synthetic Resin: Copolymer Resin

- Characteristic: Thermoplastic Resin

- Color: Light Yellow

- Softening Point(°c): 95-105

- Acid Value(Mg KOH/G): Max. 0.3

- Transport Package: 25kg Per Paper Bag

- Origin: Changzhou, China

Industrial C5 / C9 Hydrocarbon Resin Pressure Sensitive Adhesives HG100-5

Quick Detail:

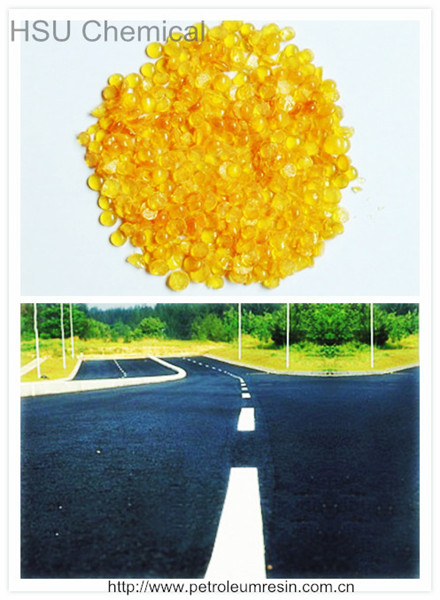

HSU™ HG100-5 is C5/C9 co-polymer hydrocarbon resin.

Description:

HSU™ HG100-5 is a light yellow granular solid thermoplastic resin, it is produced by maimly ethylene C9 fractions and fractions C5 as raw materials, through a special production process, at a certain temperature and pressure conditions, generated by the polymerization and the molecular weight range 300-3000 low molecular weight polymer. It has good compatibility with natural rubber (NR), synthetic rubber, styrene polymers (such as SIS, SBS, SEBS, EVA) and so has good compatibility with natural tackifier resins (such as: terpene resin, rosin and its derivatives) Compatibility is good. It has the advantages of the c5 petroleum resin and C9 petroleum resin. It has a low acid value, good miscibility, water resistance, resistance to chemicals, ethanol and other characteristics of the acid with a chemically stable, and adjust the viscosity and thermal stability characteristics. As the structure of non-polar groups, it is good water resistance, acid and alkali resistance, weather resistance and light aging, in organic solvents, particularly in the oil solvent, good solubility, with other resins good compatibility, but also has a certain fragility, increased viscosity, adhesion and plasticity. Generally not used alone, but as promoters, adjusting agents, modifiers and other resins used.

Applications:

The products are used in hot melt adhesives, pressure sensitive adhesives, sealants, adhesives and other civil and rubber and tire field of adhesives used as tackifying resin; for rubber, tire, radial tire especially high requirements of rubber products, not only can increase the adhesion between particles, and particles can increase with wire, tire cord adhesion between; in hot melt, adhesive, adhesives, this product can not only provide better initial viscosity, but also as rosin resins, as can be used to adjust the viscosity of the mixture of glue and resin bond strength and durability. Apply hot melt road marking paint and hot-melt road marking paint base oil; especially products made with hot-melt road marking paint the base oil and the use of C5 petroleum resin oil base compared to hot melt road marking paint, so paint and surface have a stronger The combination of strength and impact resistance, stronger, more effective to prevent the paint off the problem. In addition the product also can be used in paint, inks, such as printing inks, gravure inks, ink copperplate printing of high-grade printing inks.

Specifications:

Grade No. |

Softening Point(°C) |

Color G# |

Acid Value(mg KOH/g) |

HSU™ HG100-5 |

100±5 |

5# Max |

Max. 0.3 |

Competitive Advantage:

• Excellent compatibility with EVA and SBC rubber.

• Good chemical stability

• High heat resistance and water resistance

• Excellent tack and peel properties

• Low volatility and low odor